Assisting Roll (wire reeling device)

Assisting Roll (wire reeling device)

The Assisting Roll is electronic device for changing a dryer forming fabric. It is developed to increase safety and easiness for changing wires.

The Assisting Roll is mounted to a pillars of a basement with quick locks and it is calibrated horizontally and vertically with the help of an integrated bubble levels and measuring tools. When the device is positioned, the old wire is attached to holes of a reeling pipe in the Assisting Roll and the other end of the old wire is attached to the new wire, which is reeled on the roll. By turning a switch of a control box of the Assisting Roll, the old wire is reeled to the reeling pipe while the new one is pulled by the old wire into the paper machine.

We also have a similar device for removing press felts including a roll with spikes or holes without a transport trolley.

Bearing housings for scraper

Bearing housings for scraper

Acid-proof bearing housings for scrapers last forever. The size of the body of the housing is standard and therefore it is easy to install with different mounting plates. On the inner cover of the housing there is a break ring, which removes dirt and paste from an axis while the scraper is oscillating and thereby keeps the seal in good condition.

- Structure EN1.4404, acid-proof stainless steel

- No rust splattering

- No problems of stuck

- No seal breaks, thanks to the break ring

- Radial ball bearings

Cutting devices

Cutting devices

- Available in various position-dependent models

- Pneumatic function (striking)

- Can be connected to the machine automation

- Flat basic structure

Tensioning devices

Tensioning devices

We develop and manufacture tensioning devices for the forming, press and dryer section. Our family of products includes vertical, lever, automatic and linear tensioners. Electric, hydraulic or pneumatic motors can be used to operate the system. The tensioning devices are made of acid-proof stainless steel.

Tissue exchange openings

We replace rusty tissue exchange openings with new acid-proof ones.

- Type EN1.4404, stainless steel

- Rust-free surfaces

- Ergonomic spacers

- Removal of vibrations through precise adjustments

- Adjustment of the edge suspension

- Necessary changes to the jack lifter positions

- Working eyebolts

- Repairing of mating surfaces of washers

If necessary, we also fix roll alignments.

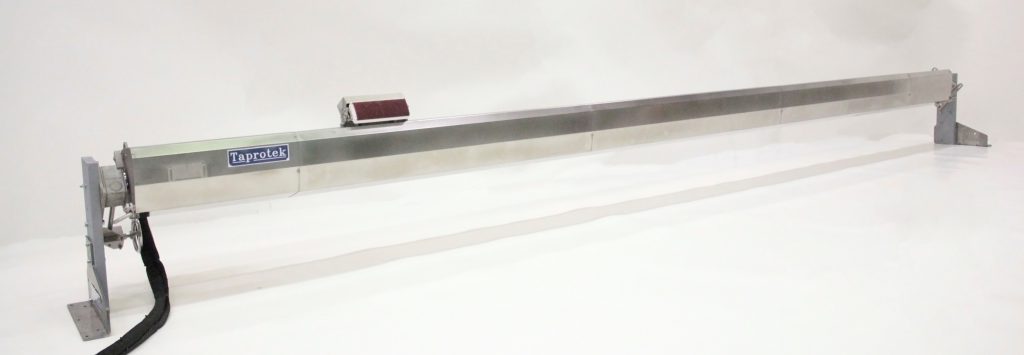

Quick Cleaner (roll cleaning device)

Quick Cleaner (roll cleaning device)

The Quick Cleaner is a roll cleaning device designed and manufactured by Taprotek Oy. With the Quick Cleaner roll cleaner, the rolls can be cleaned while the machine is running. The rolls are cleaned with traversing movements along the roll surface. The process is based on a grinding cleaning head, which moves in the cross direction of the machine and removes dirt from the surface of the roll.

Cleaning rolls during operation contributes the production growth, reduces costs and need for manual cleaning. Overall safety is also improved in various ways with the help of the Quick Cleaner. When the surfaces of the rolls are staying clean, the quality of the end-product is consistent. It also increases production capacity, when the need of changing rolls is decreasing.

Thanks to its compact size, Quick Cleaner is suitable for many applications and is particularly maintenance-free.

- Structure EN1.4404, acid-proof stainless steel

- Motor and gear made of acid-proof stainless steel, IP69K

- Cleaning tool is changeable; a scraper, an adhesive pad or a sponge

- The Quick Cleaner is also available with a vacuum unit

Equipment for roll changing

The roll changing beam is inserted into the machine in such a way that the working is safe, uncomplicated and fast. There are pull points at both ends of the roll carrier.

- Type EN1.4404 stainless steel

- Rust-free

- No problems with getting stuck

- Can be equipped with steam pipes to avoid condensation water.

- Available for different loads

Tail thread cutter

The automatic Tail thread cutter cuts and spreads the web in a cross direction of the machine.

- Structure EN1.4404, acid-proof stainless steel

- Motor and gear made of acid-proof stainless steel, IP69K

- Rust-free

- No problems with getting stuck

- Easy to maintenance, a drive and a hose reel outside of the machine

Roll trolleys

Roll trolleys

Trolley for moving and transporting rolls. The trolleys are available with two or four swivel wheels.

- Rubber padding on the trolley

- Airless rubber wheels available in soft or hard versions

- Directional lock on the wheels

Pulling points at both ends

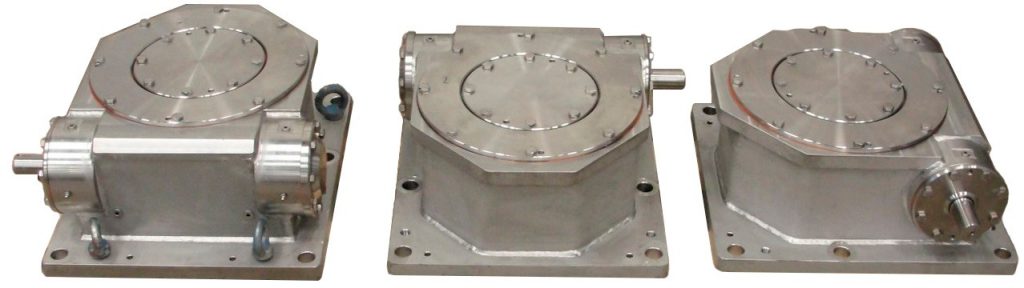

Tilt Gear (turning device for vacuum box)

Tilt Gear (turning device for vacuum box)

The Tilt Gear rotating device allows the vacuum box to be rotated 180 degrees, which makes it easier to keep the box clean. The Tilt Gear family includes pneumatic and hydraulic turning devices.

- Structure EN1.4404, acid-proof stainless steel

- Rust-free

- No problems with getting stuck

- Low structure adjustable with a raising part / position

- Adapting clutches according to each machine

- Turn 180 degrees

- Hydraulic turning force: 100 bar = 3000 nm, max 200 bar

Pneumatic turning force: 6 bar = 520 nm, max 12 bar

Safety

We highly pay attention to working safety.

Does your workplace show deficiencies in the protection of machines and their moving parts? Do you have conveyors, washers, rotating axles, rolls, pulleys, headbox ropes, blades, etc. with insufficient protection?

Without adequate protection, there is always a risk of an accident.

We supply protective devices and safety equipment for various industrial environments.

- Axle protection devices

- Work platforms and walkways

- Rope guards

- Gap protection devices

- Mesh walls

- Blade protection

Wire control valve

Wire control valve

Robust air distribution valve is an opening type. The valve controls the function of an automation controller. The distance between the maximum positions of a limit flap and the wire edge is approx. 100 mm. When the wire is in the right position in transverse direction of the machine, the flap is on halfway of its operating range.

- Structure EN1.4404, acid-proof stainless steel

- Rust-free

- No problems with getting stuck

- Very hard and robust chrome oxide coating on the flap

- Low compressed air consumption